High-Precision Surface Mount Assembly Services

What is Surface Mount Assembly?

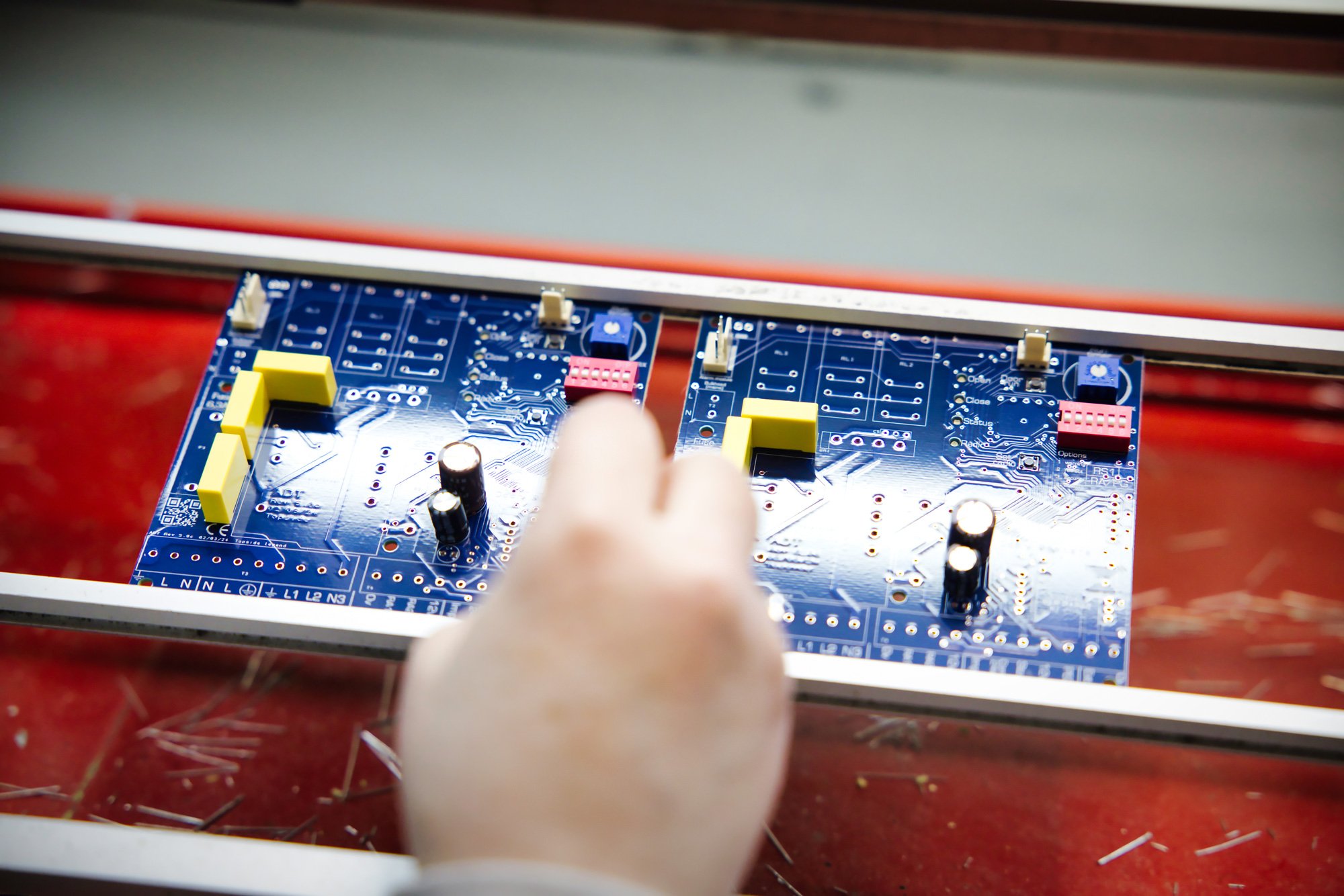

Surface Mount Assembly (SMA) is a highly efficient method of assembling printed circuit boards (PCBs) where components are directly mounted onto the board’s surface. This technique is widely used in modern electronics manufacturing due to its ability to handle high-density, compact designs while maintaining excellent electrical performance.

At First Choice Assembly, we offer state-of-the-art SMT assembly services, combining precision, speed, and quality assurance to deliver exceptional PCB manufacturing solutions.

Our Surface Mount Assembly Capabilities

High-Speed SMT Assembly

Our production facility is equipped with Yamaha iPulse pick-and-place machines, capable of placing up to 22,000 components per hour with accuracy down to 0.3mm pitch. This enables us to handle complex PCB designs while ensuring fast turnaround times.

Advanced Solder Paste Application

To ensure perfect solder joints, we use DEK265 fully automatic screen printers, applying solder paste or glue with precision. Our laser-cut, optically inspected stainless steel stencils enhance print accuracy and consistency.

Automated Optical Inspection (AOI)

Quality control is critical in SMT assembly, which is why every PCB undergoes rigorous Automated Optical Inspection (AOI) to detect:

- Component misalignment

- Solder defects

- Polarity and placement issues

- Missing or incorrect components

By integrating AOI technology into our workflow, we eliminate defects before final product assembly.

Prototype & Small-Batch Surface Mount Assembly

We understand the importance of fast prototyping in the development phase. Our SMT assembly lines are optimised to accommodate low-volume production and rapid prototyping, ensuring design validation before full-scale manufacturing.

Hybrid PCB Assembly

For applications that require both SMT and through-hole components, we offer hybrid PCB assembly solutions. Our dual-wave soldering process ensures robust connections for mixed-technology PCBs.

Interested in our Surface Mount Assembly services?

Get in touch with our team and we can supply a detailed quote for your project requirements.

Contact

Benefits of Surface Mount Assembly

- Compact PCB Designs: Reduces board size and weight, making it ideal for portable electronics.

- Higher Component Density: Maximises circuit functionality within smaller form factors.

- Enhanced Electrical Performance: Reduces signal delays and electromagnetic interference.

- Faster Manufacturing Process: Automated SMT assembly speeds up high-volume production.

- Improved Reliability: Strong solder connections enhance PCB durability and longevity.

Industries We Serve

Our Surface Mount Assembly services support a variety of industries, including:

- Automotive: Engine control units (ECUs), infotainment systems, and EV battery management systems.

- Medical Devices: High-precision SMT PCBs for diagnostic, monitoring, and imaging equipment.

- Consumer Electronics: Smart home devices, wearable tech, and IoT solutions.

- Industrial Automation: Robotics, automation controls, and sensor technology.

- Aerospace & Defence: High-reliability PCBs for mission-critical applications.

Why Choose First Choice Assembly?

With over 30 years of experience, First Choice Assembly has built a reputation for delivering high-quality SMT assembly solutions with a focus on precision, efficiency, and innovation.

What sets us apart:

- ISO 9001:2015 Certified: We adhere to the highest quality management standards.

- Advanced SMT Technology: Cutting-edge pick-and-place and inspection systems ensure accuracy.

- Scalable Production: From prototyping to high-volume manufacturing, we accommodate all needs.

- Custom Solutions: We tailor SMT assembly processes to meet specific client requirements.

- Fast Turnaround Times: Strategically located in the West Midlands**, offering same-day delivery options.

Why choose FCA?

From concept to completion

At First Choice Assembly, we support your project every step of the way. Our skilled team collaborates with you to transform initial ideas into detailed designs, ensuring each PCB meets precise specifications. We handle material sourcing, prototyping, and full-scale assembly in-house, guaranteeing quality and efficiency at every stage.

With rigorous testing and lifetime assurance on all products, we deliver reliable solutions that meet industry standards and bring your vision to life.

Full Turnkey Solutions

First Choice Assembly offers complete end-to-end PCB solutions, handling everything from design and sourcing to assembly, ensuring a seamless, efficient process for clients.

Bespoke Design In-House

First Choice Assembly’s expert team provides custom PCB designs tailored to unique project specifications, bringing flexibility and precision to every build.

Lifetime Assurance

Our commitment to value is backed by a lifetime warranty against manufacturing defects. Underscoring our commitment to quality and providing long-term reliability for all manufactured products.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors.