Surface mounted PCB assembly services.

At First Choice Assembly, we understand that evolving technology requires equally advanced solutions. As components become more compact and complex, we are committed to delivering precise, high-quality PCB assembly using the latest equipment and techniques.

From initial prototype stages to full-scale production, our facilities are optimised for speed, accuracy, and flexibility, ensuring every project meets the highest standards. Explore our advanced capabilities and see how our expertise can support your specific assembly needs.

Surface Mount Precision with Yamaha’s iPulse Technology

We utilise ten Yamaha iPulse pick-and-place machines, capable of placing components from 0201 sizes to large 54mm QFPs with speeds up to 22,000 components per hour per machine. The system’s advanced vision alignment enables accuracy down to 0.3mm pitches and 0.8mm BGA row spacing.

Flexible Prototyping and Mid-Volume Production

Our setup is optimised for both small prototype runs and mid-volume production, offering flexibility to meet diverse project needs. For prototypes, we also offer combined machine and hand placement services to allow maximum flexibility and precision placement.

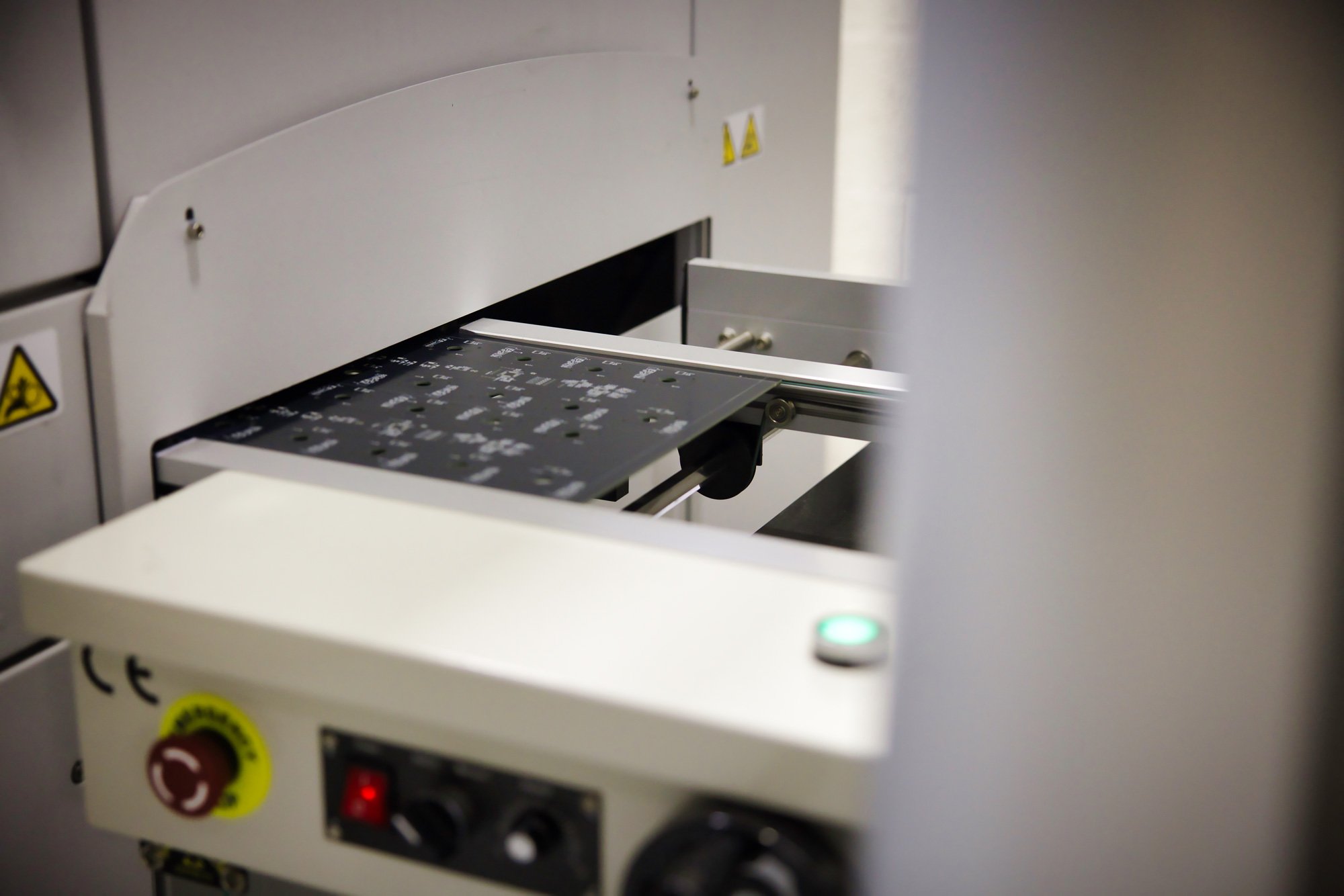

High-Accuracy Screen Printing

Equipped with DEK NeoHorizon 03 iX fully automatic screen printer, we ensure precise solder paste or glue application. Laser-cut, optically inspected stainless steel stencils, tensioned by Zelflex frameless technology, ensure each print’s accuracy and consistency across batches.

Comprehensive Inspection with AOI

Each assembled PCB can undergo Automatic Optical Inspection (AOI), checking solder integrity, component alignment, and even component values, to maintain the highest quality and reliability.

Interested in our surface mount assembly services?

Get in touch with our team and we can supply a detailed quote for your project requirements.

Contact

Why choose FCA?

From concept to completion

At First Choice Assembly, we support your project every step of the way. Our skilled team collaborates with you to transform initial ideas into detailed designs, ensuring each PCB meets precise specifications. We handle material sourcing, prototyping, and full-scale assembly in-house, guaranteeing quality and efficiency at every stage.

With rigorous testing and lifetime assurance on all products, we deliver reliable solutions that meet industry standards and bring your vision to life.

Full Turnkey Solutions

First Choice Assembly offers complete end-to-end PCB solutions, handling everything from design and sourcing to assembly, ensuring a seamless, efficient process for clients.

Bespoke Design In-House

First Choice Assembly’s expert team provides custom PCB designs tailored to unique project specifications, bringing flexibility and precision to every build.

Lifetime Assurance

Our commitment to value is backed by a lifetime warranty against manufacturing defects. Underscoring our commitment to quality and providing long-term reliability for all manufactured products.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors.